Power plants face growing challenges, and “PC tangential-fired LNB OFA ESP-CS FGC FGD-WS” is more than just a jumble of letters.

It’s at the heart of cleaner, more efficient coal-fired power generation.

So, what’s the big deal?

Let’s dive in by peeling back the layers of this crucial technology that keeps the lights on while battling pollution.

If you’ve ever wondered how modern coal plants manage to stay efficient while reducing environmental impact, this article is for you.

What Is a Tangential-Fired Boiler?

Think of a pc tangential-fired lnb ofa esp-cs fgc fgd-ws boiler like a well-organized dance.

Here, pulverized coal (PC) gets fired tangentially towards the furnace’s center, giving off a swirling flame.

It’s like creating a tornado of heat that ensures an even burn.

But there’s a catch: traditional coal combustion produces a lot of nitrogen oxides (NOx), a key contributor to smog.

That’s where the Low-NOx Burner (LNB) comes in.

How Does a Low-NOx Burner (LNB) Work?

An LNB is like a bouncer at the combustion party.

It controls how much air and fuel mix, slowing the combustion process to limit NOx formation.

The result?

You still get the power you need without the nasty byproducts.

Sounds simple, right?

But to meet strict emission standards, plants can’t stop at LNBs alone.

This brings us to the next player.

Overfire Air (OFA): Cleaning Up the Aftermath

Overfire air (OFA) adds another layer of control.

Once the coal has mostly burned, OFA injects air above the flame.

This secondary air burns off the remaining fuel, reducing NOx even further.

If LNB is the first line of defense, OFA is the clean-up crew.

Together, they form a solid one-two punch for reducing NOx emissions.

But, of course, emissions aren’t just about NOx.

Electrostatic Precipitators (ESP): Capturing the Fine Dust

Coal combustion also releases fine particles like fly ash, which can wreak havoc on air quality.

Enter the electrostatic precipitator (ESP).

Think of ESP as a giant vacuum cleaner.

As flue gas passes through, electric charges pull the ash particles from the gas, trapping them on metal plates.

It’s a critical step in keeping particulate emissions down and preventing these particles from drifting out into the environment.

ESP-CS: What Does “CS” Mean?

“CS” in ESP-CS stands for “Cold-Side.”

Cold-side ESPs work best at lower temperatures, making them perfect for installations downstream of air heaters, where the gas is already cooled.

By operating under cooler conditions, these systems are more efficient at capturing ash.

This helps reduce harmful particulates from reaching the atmosphere.

Flue Gas Conditioning (FGC): A Hidden Helper

Ever noticed how static electricity can make your hair stand on end?

That’s how flue gas conditioning (FGC) works, only on a much bigger scale.

FGC systems tweak the properties of flue gas to help the ESPs work better.

They might add small amounts of ammonia or sulfur trioxide to boost ash particle attraction.

In short, FGC is a wingman to ESP, helping to clean up flue gas more efficiently.

But there’s still one big issue to tackle.

Flue Gas Desulfurization (FGD): Scrubbing Away the Sulfur

If you’ve heard the term “scrubbers” in relation to coal plants, that’s your Flue Gas Desulfurization (FGD) system.

FGD systems are essential for removing sulfur dioxide (SO2) from flue gases.

Without these systems, coal plants would spew acid rain-inducing sulfur compounds into the atmosphere.

Wet scrubbers pc tangential-fired lnb ofa esp-cs fgc fgd-ws use a liquid, usually limestone slurry, to capture and neutralize the sulfur.

The process creates gypsum as a byproduct, which can then be used in construction materials like drywall.

Yes, something good can come out of something so bad!

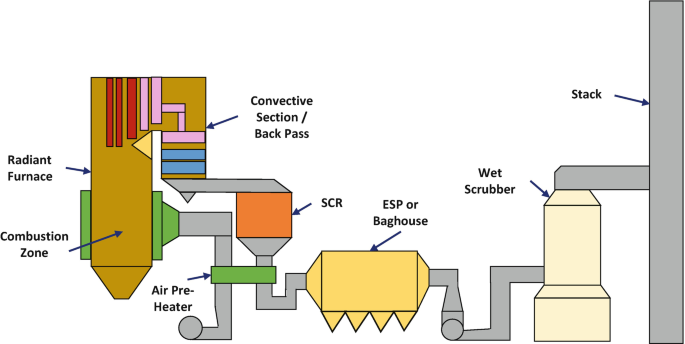

Why This Matters: PC Tangential-Fired LNB OFA ESP-CS FGC FGD-WS Together

The combination of these technologies – tangential firing, LNB, OFA, ESP-CS, FGC, and FGD-WS – creates a finely tuned machine designed to maximize energy efficiency while minimizing emissions.

By working in harmony, these systems significantly reduce pollutants like NOx, SO2, and particulates.

Power plants adopting this full suite of technologies can meet stringent emission limits without compromising their ability to generate electricity.

But what does this mean for you, the reader?

Real-Life Example: How It Works at Your Power Plant

Let’s say you live near a coal-fired power plant.

Before they upgraded to this full suite of emissions controls, you might have noticed a haze in the sky or felt the air quality wasn’t great.

After installing PC tangential-fired LNB OFA ESP-CS FGC FGD-WS systems, the air became clearer, and emissions plummeted.

The plant didn’t have to shut down.

They just got smarter about how they burn coal and clean up the exhaust.

And for you, it means cleaner air without sacrificing the reliability of electricity.

FAQs on PC Tangential-Fired LNB OFA ESP-CS FGC FGD-WS

Why is tangential firing better than other methods?

Tangential firing ensures an even heat distribution, which leads to better combustion efficiency and reduced emissions.

What’s the role of Low-NOx burners?

LNBs help lower the formation of nitrogen oxides by controlling the combustion process, reducing the heat at which NOx is produced.

Can OFA work without pc tangential-fired lnb ofa esp-cs fgc fgd-ws?

While OFA can still reduce emissions on its own, combining it with LNB provides a much more effective reduction in NOx.

Why are pc tangential-fired lnb ofa esp-cs fgc fgd-ws important?

Electrostatic precipitators capture ash and fine particles, preventing them from entering the atmosphere and reducing particulate pollution.

What does FGD-WS stand for?

Flue Gas Desulfurization – Wet Scrubber, a system that removes sulfur dioxide from exhaust gases to prevent acid rain formation.

Conclusion: The Big Picture of PC Tangential-Fired LNB OFA ESP-CS FGC FGD-WS

PC tangential-fired LNB OFA ESP-CS FGC FGD-WS may sound complicated, but at its core, it’s about making power plants cleaner and more efficient.

By using a combination of low-NOx burners, overfire air, electrostatic precipitators, flue gas conditioning, and desulfurization, coal plants can significantly cut harmful emissions.

And in a world where clean air matters more than ever, this technology is making a huge difference.

It’s a cleaner way to burn coal – and that’s a win for everyone.

PC tangential-fired LNB OFA ESP-CS FGC FGD-WS is the future of cleaner coal.